Home > Types of centrifugal fans

Different types of centrifugal fans

Centrifugal fans are available in a wide range of configurations, tailored to the application, airflow direction, mounting orientation, and environmental requirements. Think of designs with forward- or backward-curved blades, ATEX variants, motor setups (direct or belt-driven), and various discharge directions.

In this article, we explain the most common types to help you choose the right fan for your installation or project.

Common configurations

The configuration of a centrifugal fan determines, among other things:

- The motor position (direct or belt-driven)

- The discharge direction (e.g. LG 270 or RD 0 – see also discharge positions)

- The construction and mounting method (base, flange, or pedestal mounting)

- The suitability for specific applications (standard, ATEX, smoke extraction, corrosion-resistant, etc.)

Below we explain the most important types in more detail.

1. Direct-driven vs. belt-driven fans

Direct-driven centrifugal fans have the impeller mounted directly onto the motor shaft. This setup is compact, low-maintenance, and ideal for clean air applications. It’s an efficient choice for smaller systems with stable performance requirements.

Belt-driven fans, on the other hand, are ideal when airflow or pressure needs to be adjustable. With a belt drive, you can easily control the speed — and thus the airflow. This type is commonly used in industrial systems or ventilation ducts with long runs.

The images below show some standard options. Other configurations are available on request.

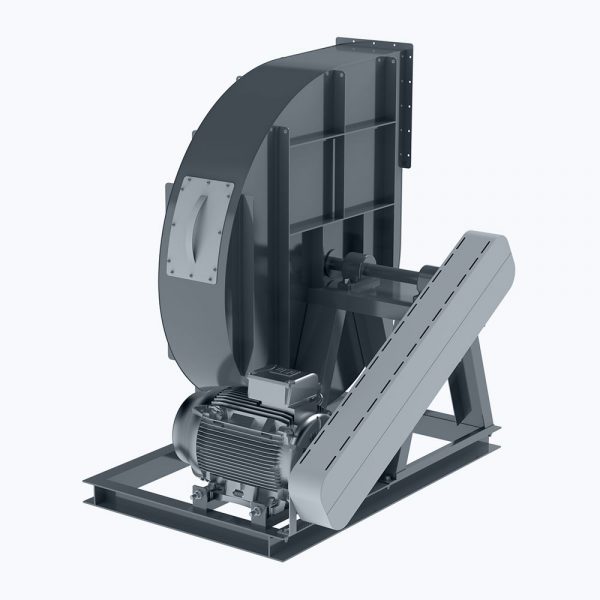

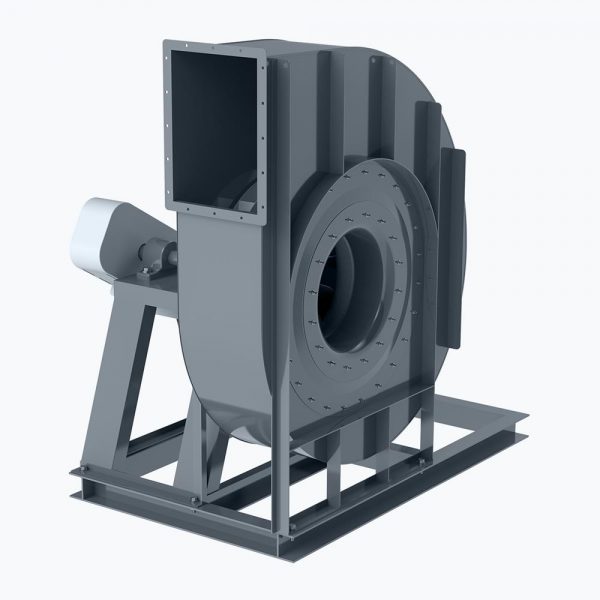

Centrifugal fan, direct-driven version 4

Centrifugal fan, direct-driven version 5

Centrifugal fan, belt-driven version 12 (or 9)

Centrifugal fan, belt-driven version 12 (or 9)

2. Backward-curved or forward-curved blades

The impeller design directly affects performance, sound level, and efficiency:

-

Backward-curved blades are more energy-efficient and require less power input. They are suitable for higher-pressure applications and industrial use.

-

Forward-curved blades deliver higher air volumes at lower pressures. These are commonly used in compact ventilation units or residential systems.

Note: The choice between blade types depends heavily on the application, noise requirements, and level of air contamination.

3. Discharge direction and rotation

Centrifugal fans discharge air at a 90° angle from the intake. The direction is indicated by a discharge position, such as LG 90 or RD 270. This is crucial for proper integration into your air handling system.

Refer to our overview of discharge positions for a visual explanation of these designations.

4. ATEX fans and special designs

In potentially explosive environments, ATEX-certified fans are mandatory. These are specially designed in compliance with ATEX Directive 2014/34/EU to minimize ignition risks in zone 1, 2, 21, or 22.

Other frequently requested special designs include:

- Smoke extraction fans compliant with EN 12101-3

- Corrosion-resistant fans, made of plastic or stainless steel

- High-temperature fans, suitable up to 400°C or more

- Fans with IP55 motors for outdoor use (see also: IP55 motors and outdoor installations)

Need help choosing the right fan type?

Not sure which fan version suits your needs? Or do you have specific requirements in terms of materials, noise, ATEX, airflow or pressure? We’re happy to advise you and offer a custom solution.

Get in touch with us or view our full range of centrifugal fans.

Need advice? Get in touch!

We’re available Monday to Friday from 8:30 to 17:00.

Frequently asked questions about centrifugal fan types

What is the difference between direct-driven and belt-driven centrifugal fans?

A direct-driven fan has the impeller mounted directly onto the motor shaft, resulting in a compact and low-maintenance setup. A belt-driven fan uses a belt to connect motor and impeller, allowing flexible speed (and airflow) adjustments.

What do LG and RD mean in centrifugal fan discharge directions?

These codes indicate the rotation and discharge position. LG stands for left (gauche) rotation, RD for right (dexter) rotation. The numbers (e.g. 90, 270) refer to the discharge angle relative to the intake. See our discharge direction guide for a clear overview.

When should I choose a fan with backward-curved blades?

These fans are more energy-efficient and suitable for higher-pressure systems. They’re commonly used in industrial installations with long duct runs. Forward-curved blades are better for compact applications with lower pressure drops.

Which fan type should I use in explosive environments?

In that case, an ATEX fan is required. These fans comply with ATEX Directive 2014/34/EU and are designed to prevent sparks or overheating in hazardous zones. Learn more on our ATEX fan information page.